This month’s makers are Caitlin Ye, Joany Xue, Selina Huang, and Honglip Park from the UCSF School of Dentistry. We caught up with the team to see what they have been making in the Makers Lab.

Q: What did you create?

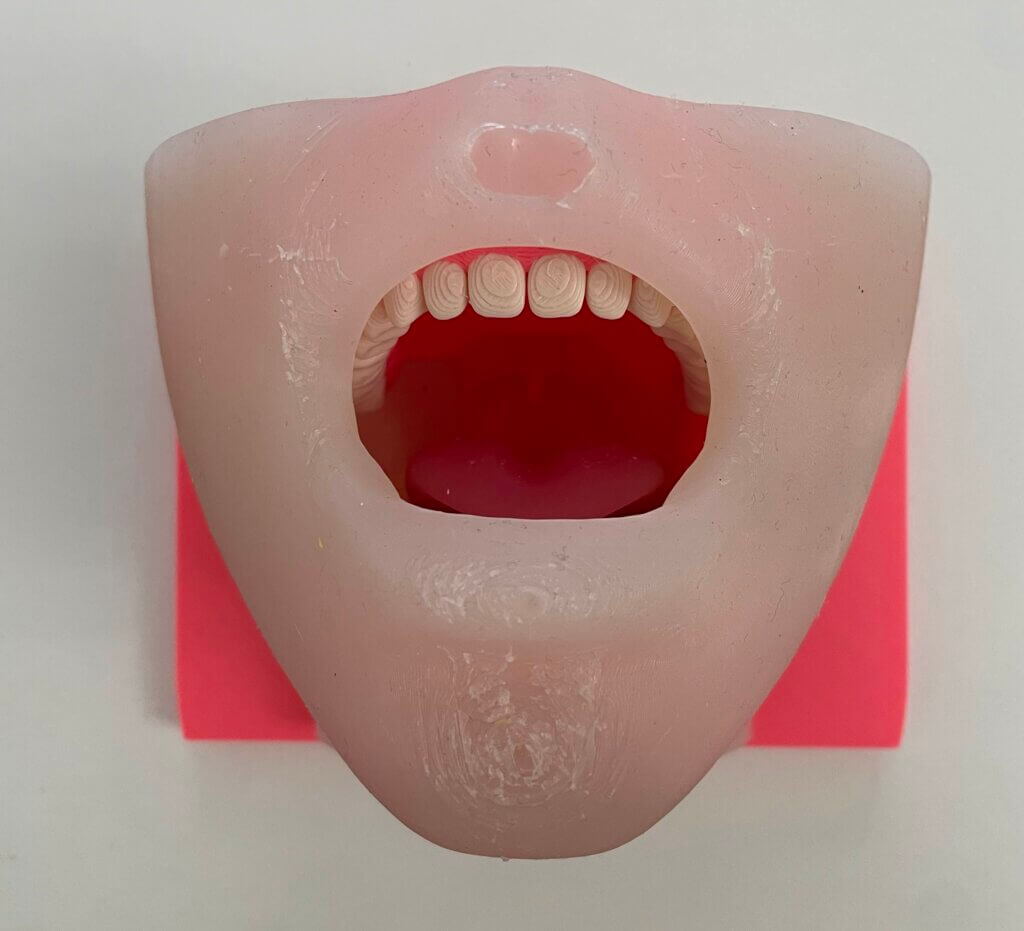

We have developed a 3D-printed simulation model for the Inferior Alveolar Nerve (IAN) block.

Q: Why did you decide to create it?

We created this simulation model to address the limitations in current training methods for administering local anesthetics. Students were not allowed to practice on their classmates, and existing mango-mandible simulations lacked the ability to visualize crucial landmarks like the pterygomandibular raphe. Additionally, simulating the retraction of the tongue and cheek during the injection was challenging. Therefore, we developed the IAN block simulation model as a supplemental aid to enhance the training process.

Q: What was your process like?

To create the simulation model, we obtained a data file representing the human oral structure and made modifications to fit our anatomical requirements. Software such as Blender and Slicer were utilized to add detailed structures and support fixtures for 3D printing. Silicone, which mimics human skin, was used to represent the non-skeletal structures, and various colors were added to replicate the appearance of real human tissue.

Q: What was the most challenging part of the process?

The most challenging aspect was finalizing the design and anticipating potential errors before printing. Lack of experience in the manufacturing process required careful consideration and comparison between our conceptualization and the practical reality. Another challenge was selecting materials that could accurately mimic the properties of human skin.

Q: What was your favorite part of the process?

One of the most satisfying moments was breaking the mold and examining the final product. This experience allowed us to reflect on our initial steps, such as brainstorming and meticulous design work.

Q: How has this project contributed to your education?

The IAN block simulation model has provided several educational benefits. It accurately simulates the depth of injection in relation to anatomical landmarks, and students can receive tactile feedback from needle penetration. This model has been particularly helpful for students struggling with administering local anesthesia, as it helps build their confidence and reduce uneasiness before treating actual patients.

Q: What do you plan to create next?

We are currently working on an enhanced version of the simulation model with Makers Lab. With the patient’s consent, we have obtained human Cone Beam Computed Tomography (CBCT) files that provide highly detailed and realistic anatomical landmarks. Leveraging this data, we are developing a more sophisticated framework for the simulation model. Our ultimate objective is to administer pre- and post-surveys to evaluate students’ confidence levels and measure the effectiveness of the 3D-printed simulation model in comparison to existing methods.