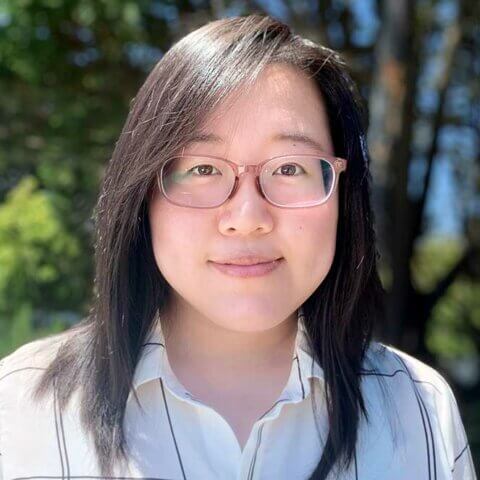

This week’s maker is Valerie Stevens, a study coordinator at the Proctor Foundation. We caught up with Valerie to learn more about the project she has been working on in the Makers Lab.

Q: What did you make?

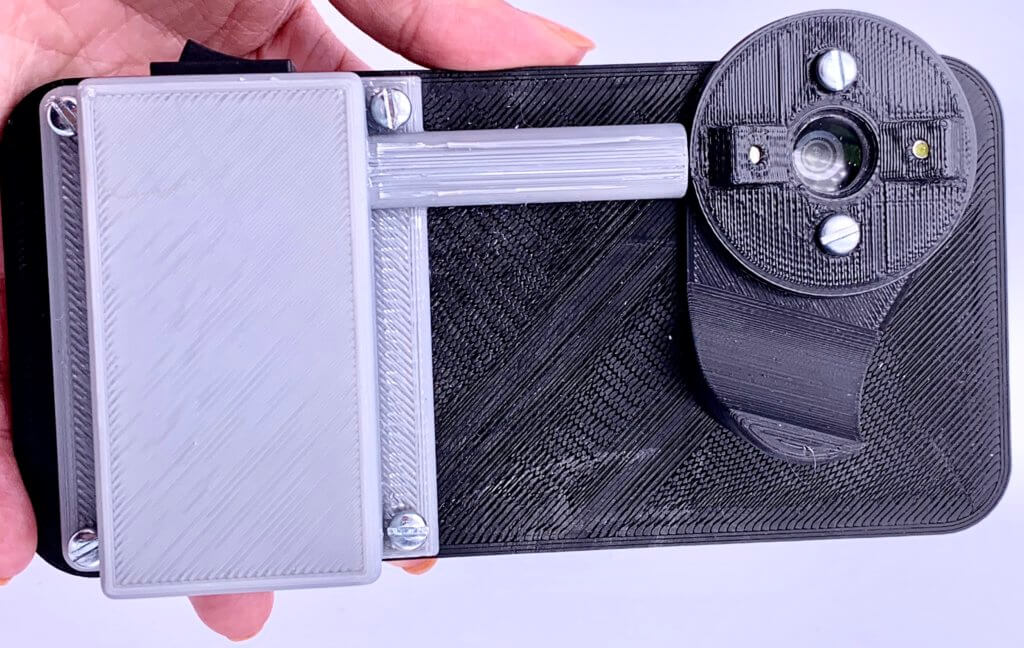

I 3D printed and built CellScopes. They are smartphone attachments that augment the phone’s built-in camera using a macro lens and LEDs. They allow the user to take high-quality images of the cornea in field settings.

Q: Why did you want to make it?

We needed new CellScopes to conduct the final outcome assessment for the Village Integrated Eye Worker Trial (VIEW). VIEW is a cluster-randomized clinical trial conducted by the Proctor Foundation. The trial seeks to evaluate whether a program employing community health workers to treat corneal abrasions can reduce the incidence of corneal ulcers in communities in Nepal. The first CellScopes we used were designed and produced by Dan Fletcher’s lab at UC Berkeley. Last year, we decided to switch to a newer smartphone model with a better camera, which required an updated CellScope.

Q: What was your process?

We worked with a designer, Pierre Grandin, to modify UC Berkeley’s CellScope design to fit the new phone. He provided the STL files as well as instructions on how to build the CellScopes once we had the 3D printed parts. However, I did not have any practical experience soldering nor was I familiar with the 3D printing resources available. Luckily, I was able to consult the Makers Lab! They taught me to solder the electronics components of the CellScope and gave me advice on 3D printing options. We used a commercial vendor to print the first batch of CellScope parts as we had a large order. We borrowed Makers Lab soldering equipment and did the soldering and construction in the office. A few of my fellow Proctor team members volunteered to help and we set up a soldering assembly line. Since then, we have built two smaller sets of CellScopes for other projects taking place in Peru and Ethiopia. For these sets, I printed the CellScope parts at the Makers Lab as well.

Q: What was the hardest part of the process?

I had never done anything like this before. 3D printing and soldering were completely new to me. I think the hardest part was learning how to build that first CellScope.

Q: What was your favorite part of the process?

It was very satisfying to see the final product in action in the field.

Q: How did this help make you a better study coordinator?

In global health research, we are often looking for cost-effective and portable tools for collecting data in low-resource settings. While I am not sure when I will next need to 3D print or solder, my experience with this project has encouraged me to think creatively and given me a broader set of skills with which to approach future problems.

Q: What do you want to make next?

I don’t have plans to make anything new soon, but I would be excited to apply the skills I learned at the Makers Lab to future projects.