This month’s maker is Kaori Takahashi, physical therapist at Alta Bates Summit Medical Center Acute Rehabilitation Physical Therapy Department who works mostly with individuals with neurological disorders. She sought out help to make her model come to fruition via a cross-collaboration with the UCSF Makers Lab.

We caught up with Kaori to see what she has been making.

Q: What did you make?

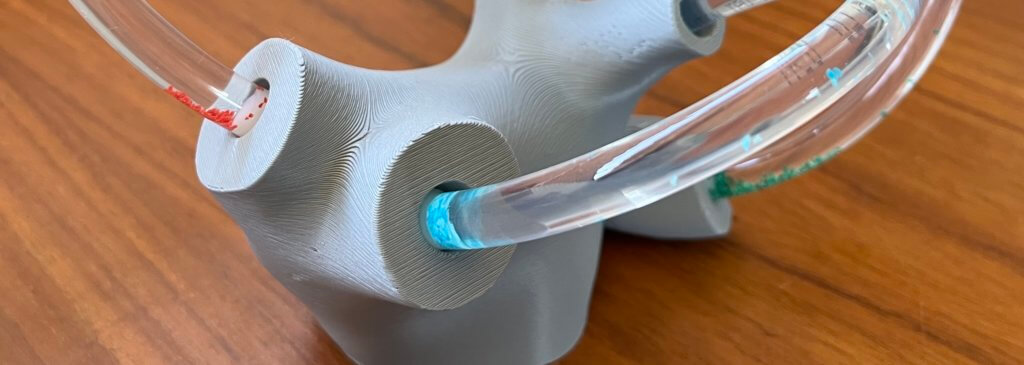

I made models of the semicircular canals which are part of the inner ear. It’s the body part of interest when someone is experiencing Benign Paroxysmal Positional Vertigo.

Q: Why did you want to make it?

I split my days between an inpatient rehabilitation facility where patients get intensive rehab prior to returning home, and an outpatient clinic where I see people living in the community. In both settings, I see patients with dizziness and vestibular issues, which led me to this project. BPPV is caused by a displacement of otoconia (crystals) from the utricle where they normally are, into the semicircular canal, which are fluid filled canals that sense rotational movement. A person with BPPV will experience dizziness or vertigo triggered by changes in head position, and the treatment can be fairly simple. By moving through a series of specific head positions the displaced crystals can be cleared out of the canal, and if successful, will cure that episode of BPPV. However, these repositioning maneuvers can trigger severe dizziness and nausea, so it is critical for the person to understand the value of the treatment before it is performed. Also, for me as the clinician, it really helps to see the structures in 3D.

Q: What was your process?

There was a free resource on Vestibular First that took me through the step-by-step directions of making the model. I ordered the materials, and followed it exactly.

Q: What was the hardest part of the process?

I was surprised how difficult it is to push an end cap through the tubing, particularly when both are filled with mineral oil and I was trying to close it up without letting in air bubbles. It took me many tries to close up each tube, and this gave me an appreciation for why the models cost $250 per pair if you order them.

Q: What was your favorite part of the process?

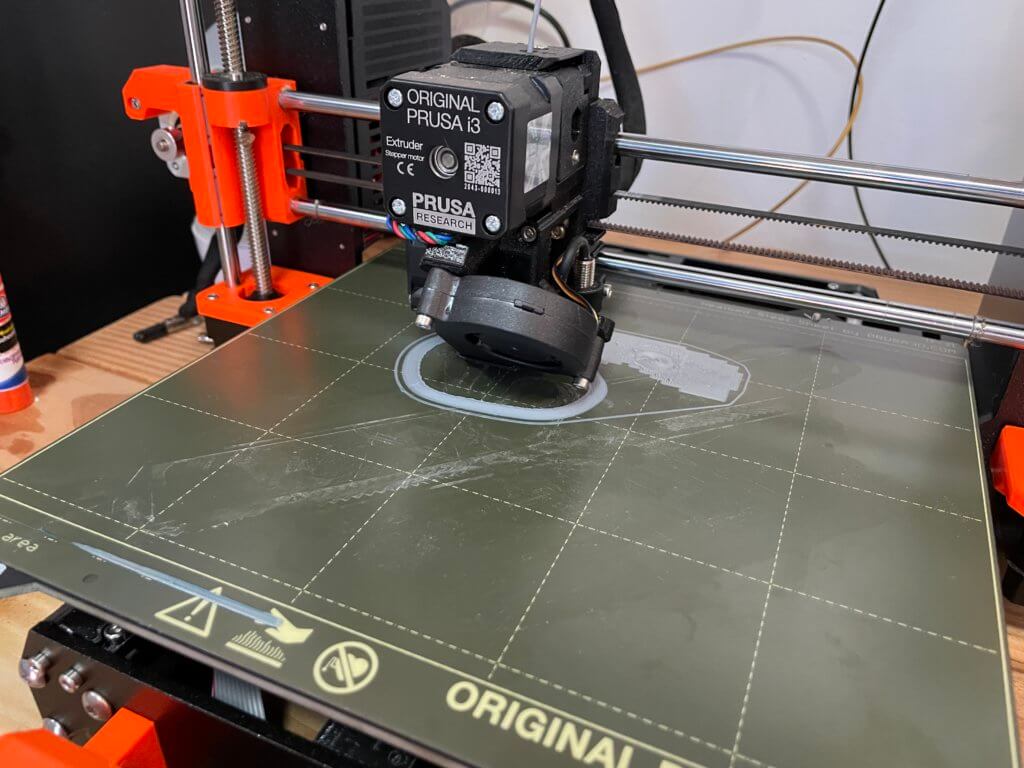

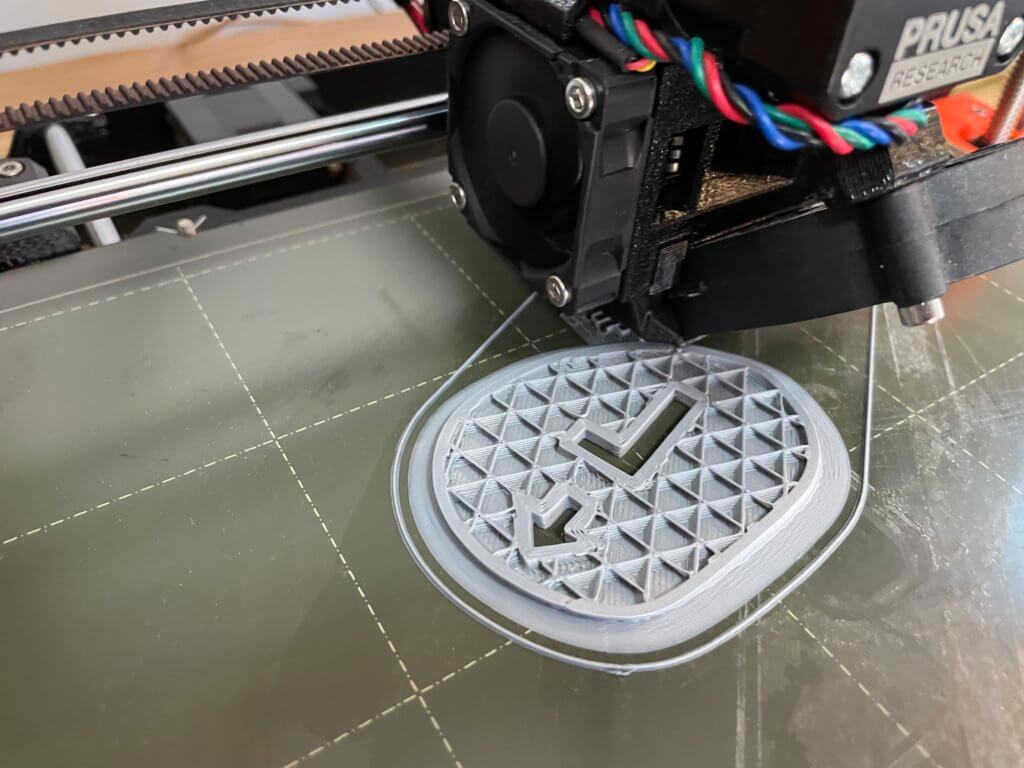

It was so neat to see the 3D printing first hand. It was also fun collaborating with a friend and seeing him working in his element.

Q: How did this help make you be better at your job?

Seeing the crystals move very slowly through the medium of mineral oil helped me to understand why it can take a minute for the crystals to settle in the desired position.

Q: What do you want to make next?

I’m not sure… but I’m confident if I come up with an idea, Scott can help me build it!