This month’s maker is Isra Raza, staff research associate at the Kotas Lab at UCSF. We caught up with them to see what they have been making in the Makers Lab.

Q: What did you make?

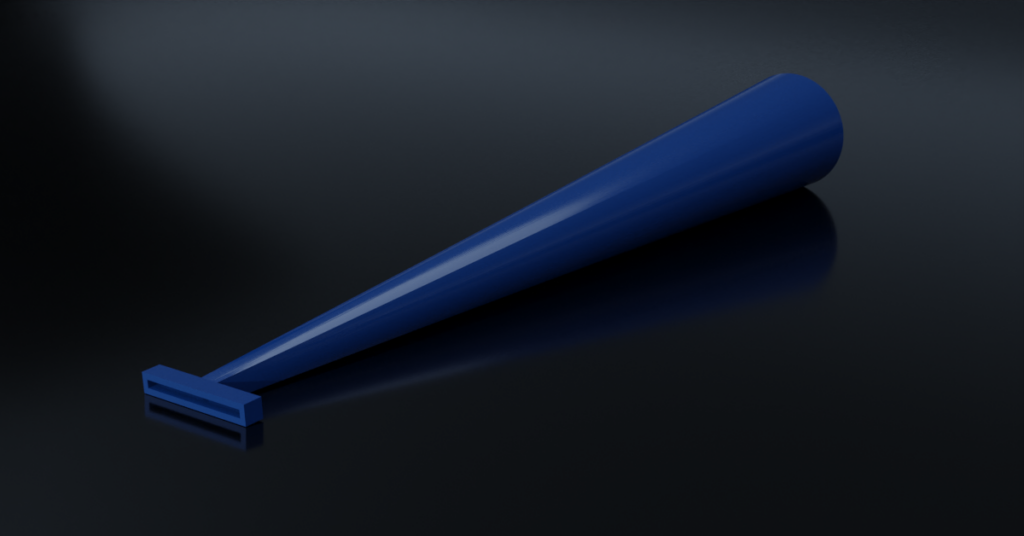

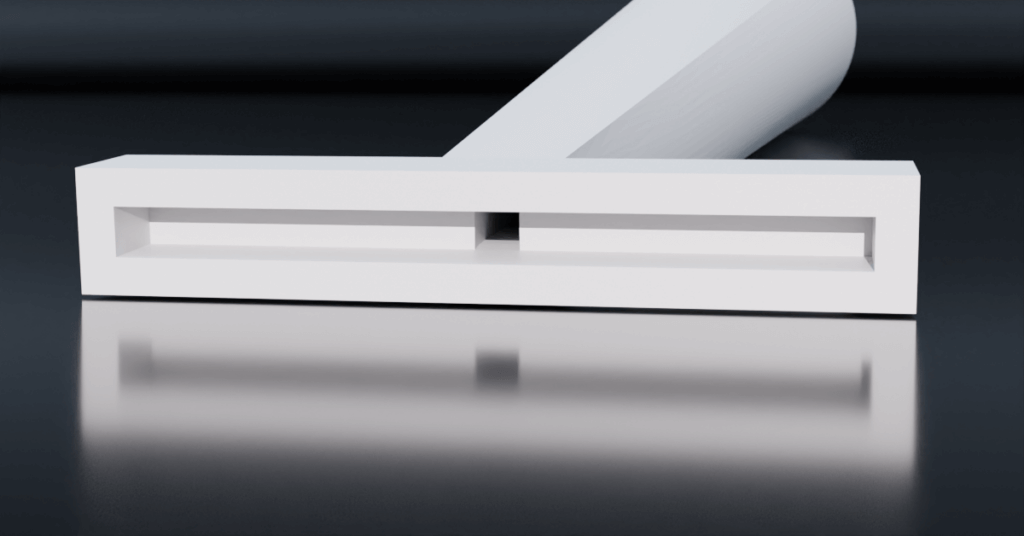

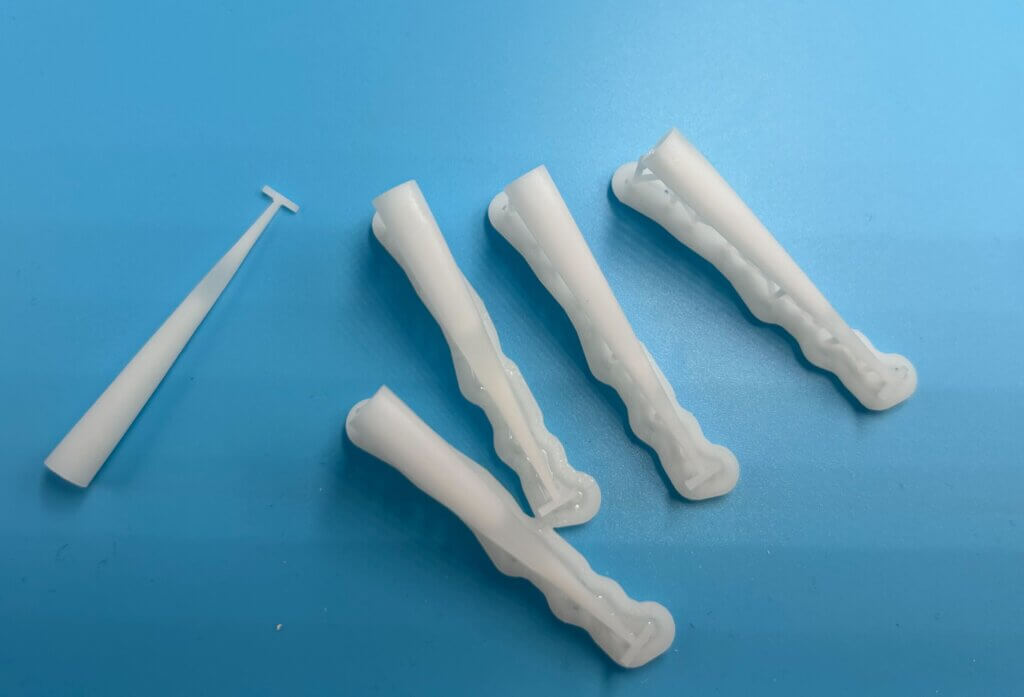

I wanted to make an aspirating tip (like the size of a P200 tip) with a rectangular opening at the bottom, similar to what a vacuum looks like. The actual 3D printable design was made by Scott Drapeau from the Makers Lab.

Q: Why did you want to make it?

I wanted to make this rectangular-ended tip because we are trying to study wound/scratch assays in our lab, and our manual scratching method (which is just us scraping over the cell membrane with a pipette tip) felt inaccurate as we couldn’t get a scratch of consistent size/shape. We looked at other methods of creating a scratch, but none of them really fit what we were looking for – until someone mentioned 3D printing a custom scratch-shaped aspirating tip.

Q: What was your process?

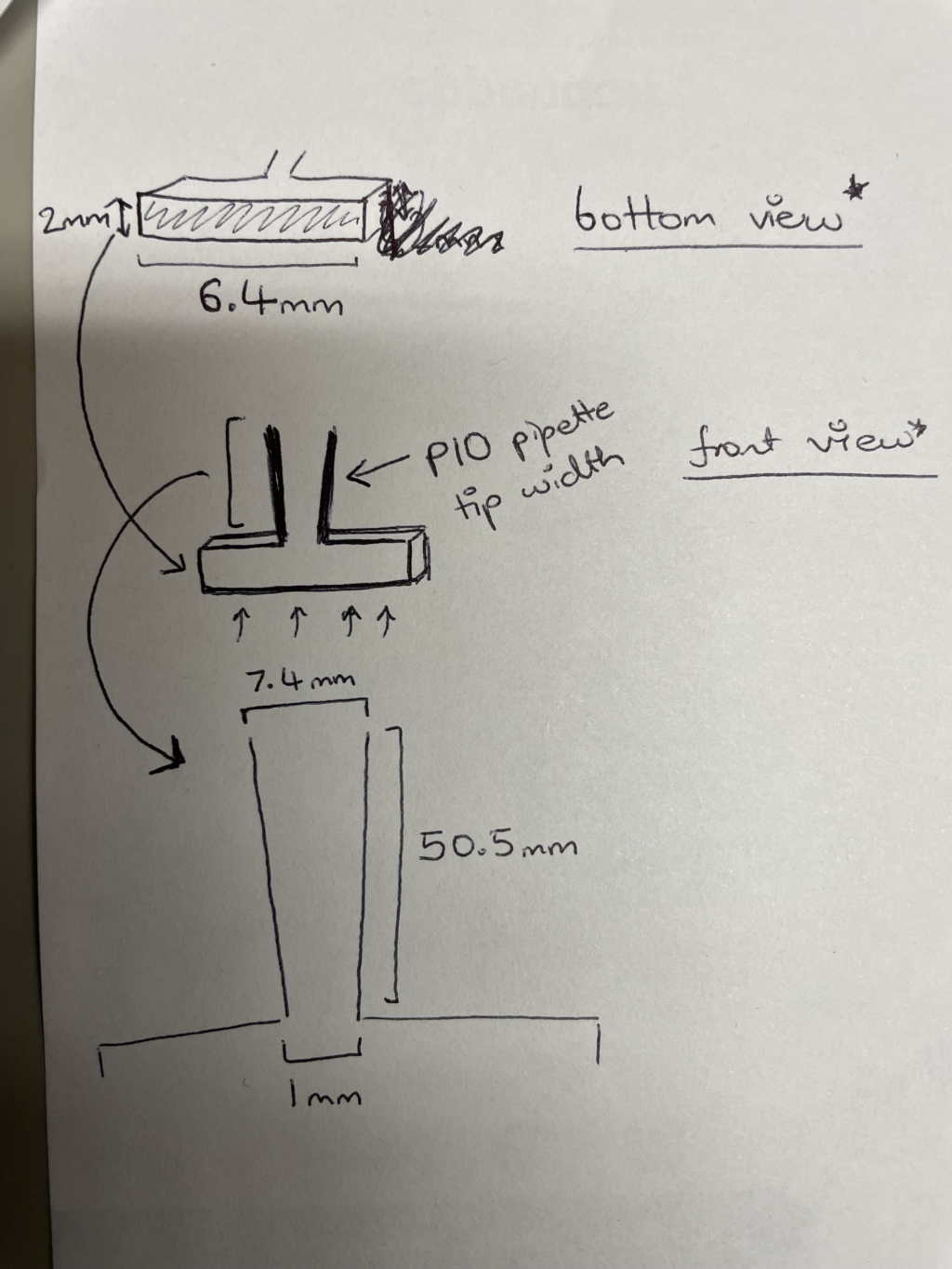

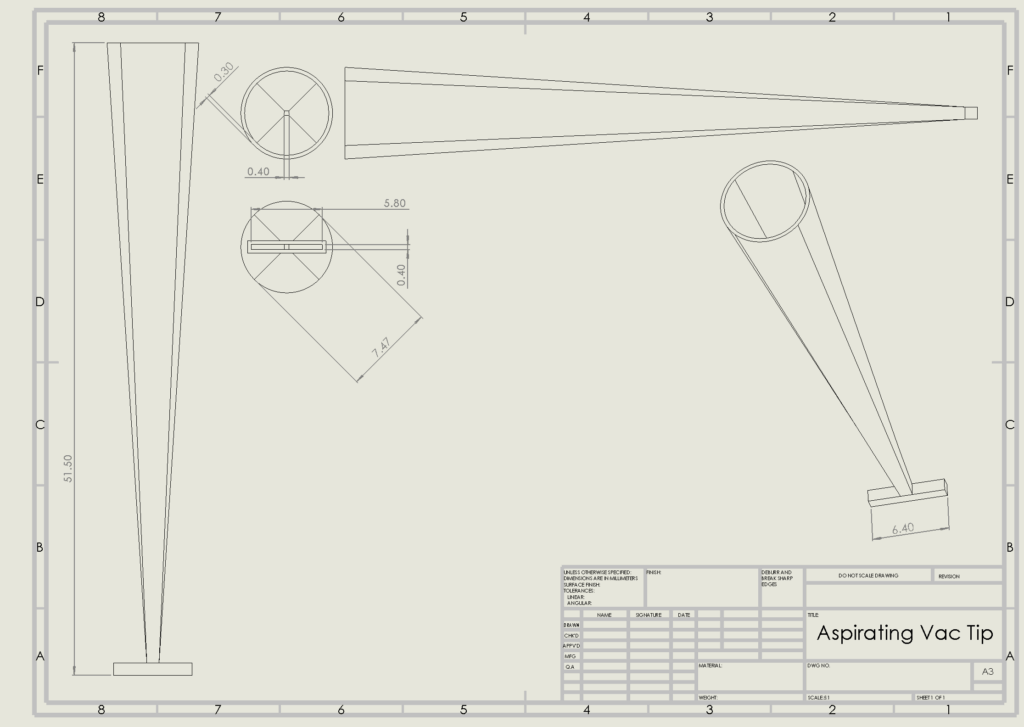

The process was first emailing the UCSF Makers Lab and sharing the design idea. From there, with Scott’s help, we drew out the basic shape of the design, and Scott modeled the specified size dimensions we wanted using SolidWorks, and then narrowed it down to a final design.

Q: What was the hardest part of the process?

The entire process was actually very easy because I received a lot of help from Scott with creating the design – for me, the most challenging part was initially trying to explain what the design idea was, but that was easily solved after I sent a sketch of what I was thinking.

Q: What was your favorite part of the process?

My favorite part was seeing the final design sketch with all the dimensions. That was when I saw – what started as an idea in my head had become something tangible.

Q: What do you want to make next?

This was my first time 3D printing, but now that I’ve tried it, there are a lot of other things I want to try next. I think the first thing will be optimizing this design, making the structure a bit more hollow (or just enough so that it pulls up cells more effectively when hooked up to a vacuum). After this, it would be cool to try other cell-culture related ideas (like making some kind of barrier that prevents cell growth in a part of the membrane) that we can use in our experiments!