This week’s maker is Ilan Benador-Shen, resident with the School of Medicine. Let’s take a look at what they made.

Q: What did you make?

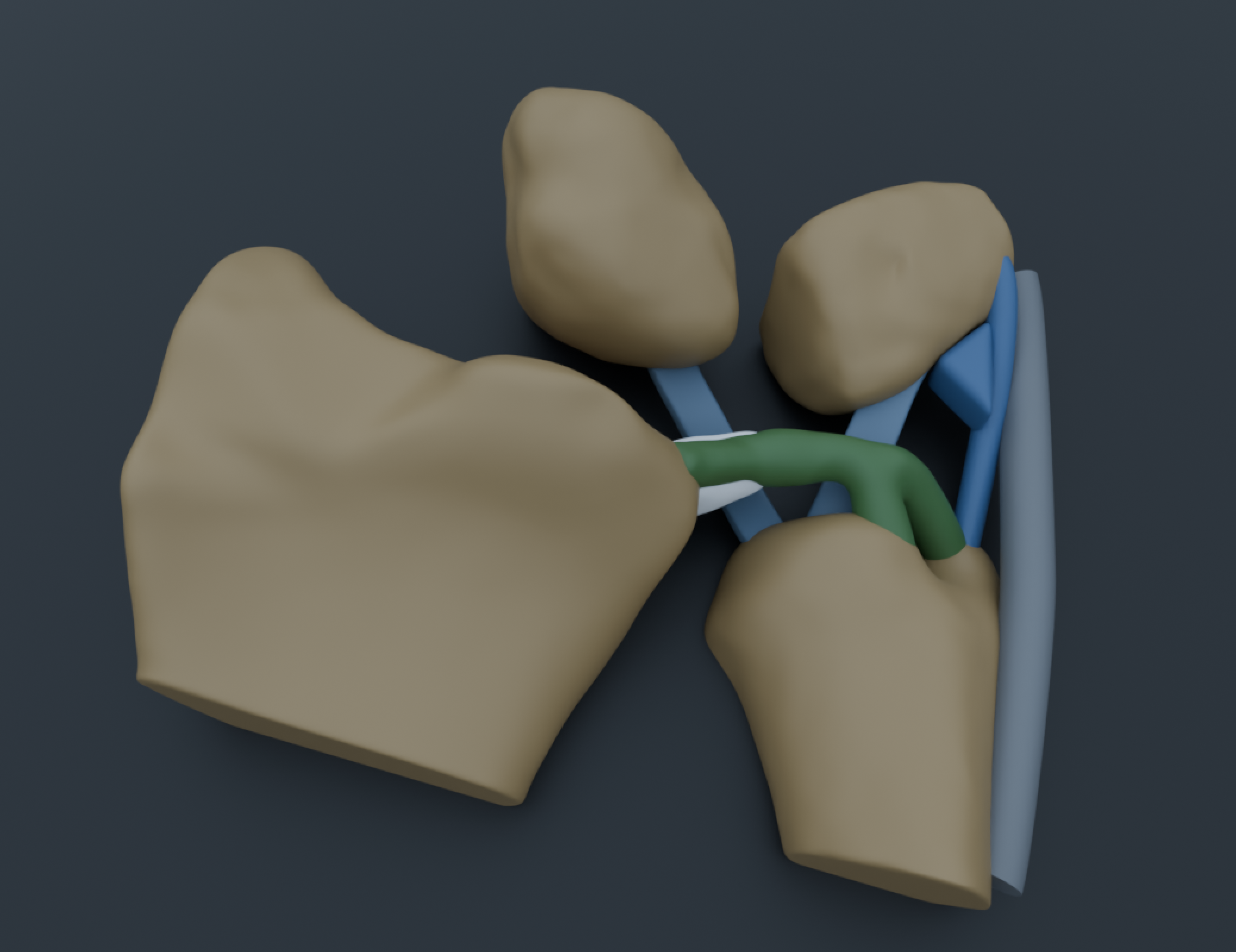

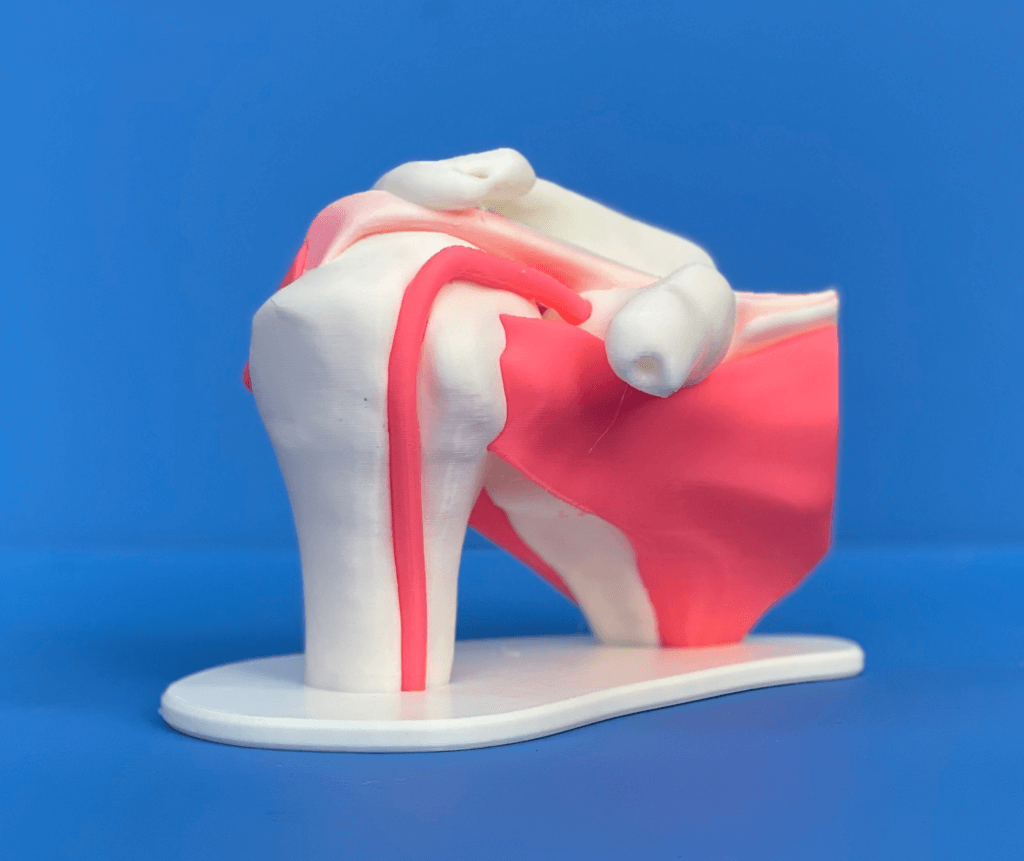

I made a multi-color educational model of the rotator cuff.

Q: Why did you want to make it?

As a radiology resident, I noticed how educators often explained injury patterns and the spatial relationships between complex anatomic structures using their hands and 2D resources such as PowerPoint slides. As a tactile learner, it was challenging for me to learn in this way. After 3 years of training, I grasped many of these concepts, but the process was slow and challenging. I believed I could enhance the learning of junior residents and make it more fun by making 3D models for the work rooms. I thought this would be especially useful for the complex anatomy evaluated by joint magnetic resonance imaging (MRI), where MR sequences are acquired in 2D planes of various obliquities and cannot be reconstructed for 3D visualization like a computed tomography (CT) scan.

Q: What was your process?

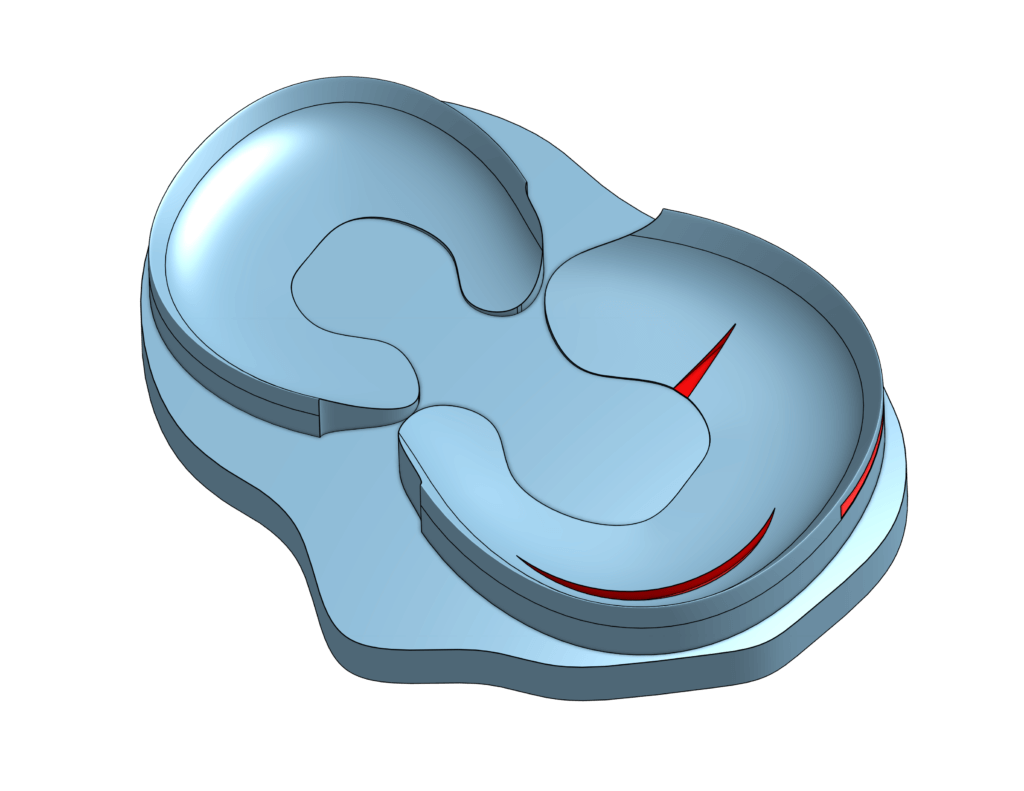

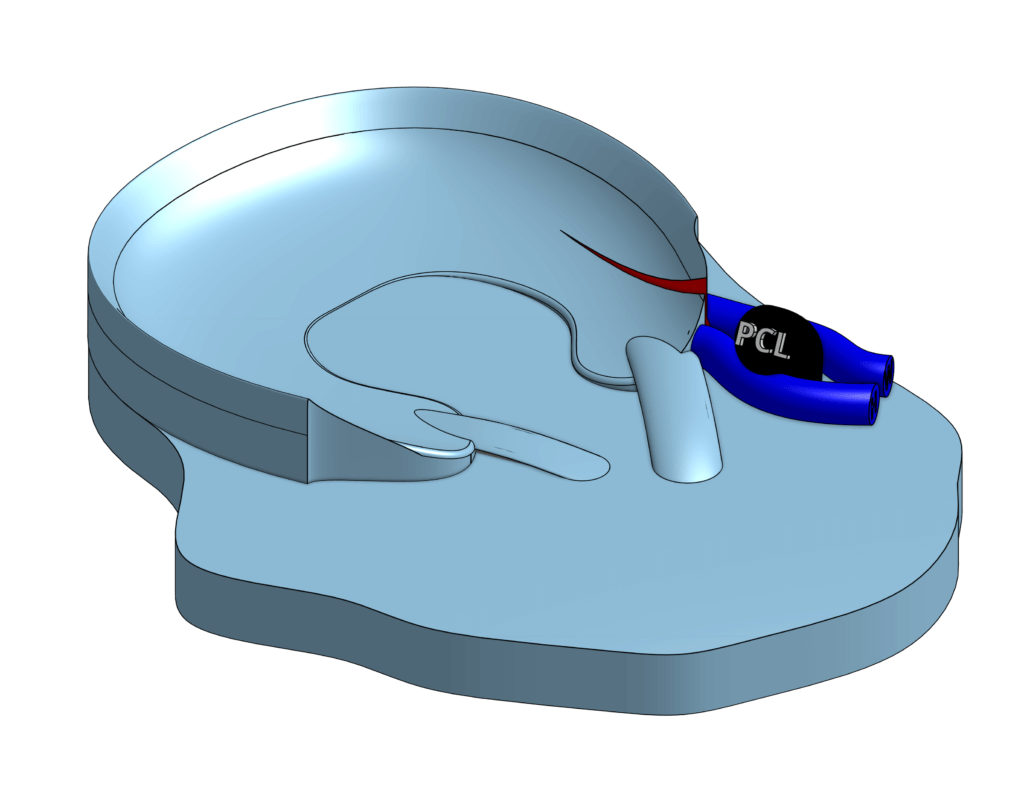

I initially started 3D modeling in OnShape to make custom parts for my espresso machine and coffee grinder. When I learned about the Makers Lab, I realized I could apply these skills to teaching and learning. I continued sketching everything by hand using OnShape and overlayed MRI images for more complex projects. I also imported premade 3D files of vascular anatomy and bones derived from CT scans from the free NIH database (3d.nih.gov). I made simple models of the meniscus of the knee with various injury types such as radial tear, horizontal tear, and vertical tear. Next, I made more complex injury patterns such as Wrisberg rips, which required multicolor printing of the meniscal ligamentous attachments.

Q: What was the hardest part of the process?

3D modeling of complex curving shapes in OnShape has been a challenge and I am still learning a lot. I learned from Scott Drapeau at the Makers Lab that Blender may be a better software for my projects and plan to use it next. Scott had a existing shoulder model from another project that he was able to quickly edit and add features that I was requesting. He then set up the multi-material print in Bambu Studio to use white and pink filaments.

Q: What was your favorite part of the process?

I really enjoyed collaborating with Jenny, Scott, and Josh on all my projects. Their incredible high skill level, enthusiasm, and creativity made every project fun to work on. I also realized that my understanding of anatomy deepened even further through the process of designing 3D models.

Q: What do you want to make next?

I’m working with Scott on more realistic anatomical models using publicly available skeletal models derived from segmented CTs. We successfully printed a model of the Lisfranc ligament, one of the most important ligaments of the foot, named after the Napoleonic-era French surgeon Jacques Lisfranc de Saint-Martin. Lisfranc injuries are important to be recognized by radiologists because they can result in disabling collapse of the foot without prompt diagnosis and surgical intervention in addition to being a leading legal liability for physicians. We are using a similar approach to create a model of the triangular fibrocartilage complex (TFCC) of the wrist, one of the most anatomically complex structures in the body, which we hope to print soon.