This week’s maker is Ben Ngu, junior specialist in the Department of Neurology at UCSF. Let’s take a look at his project:

Q: What did you make?

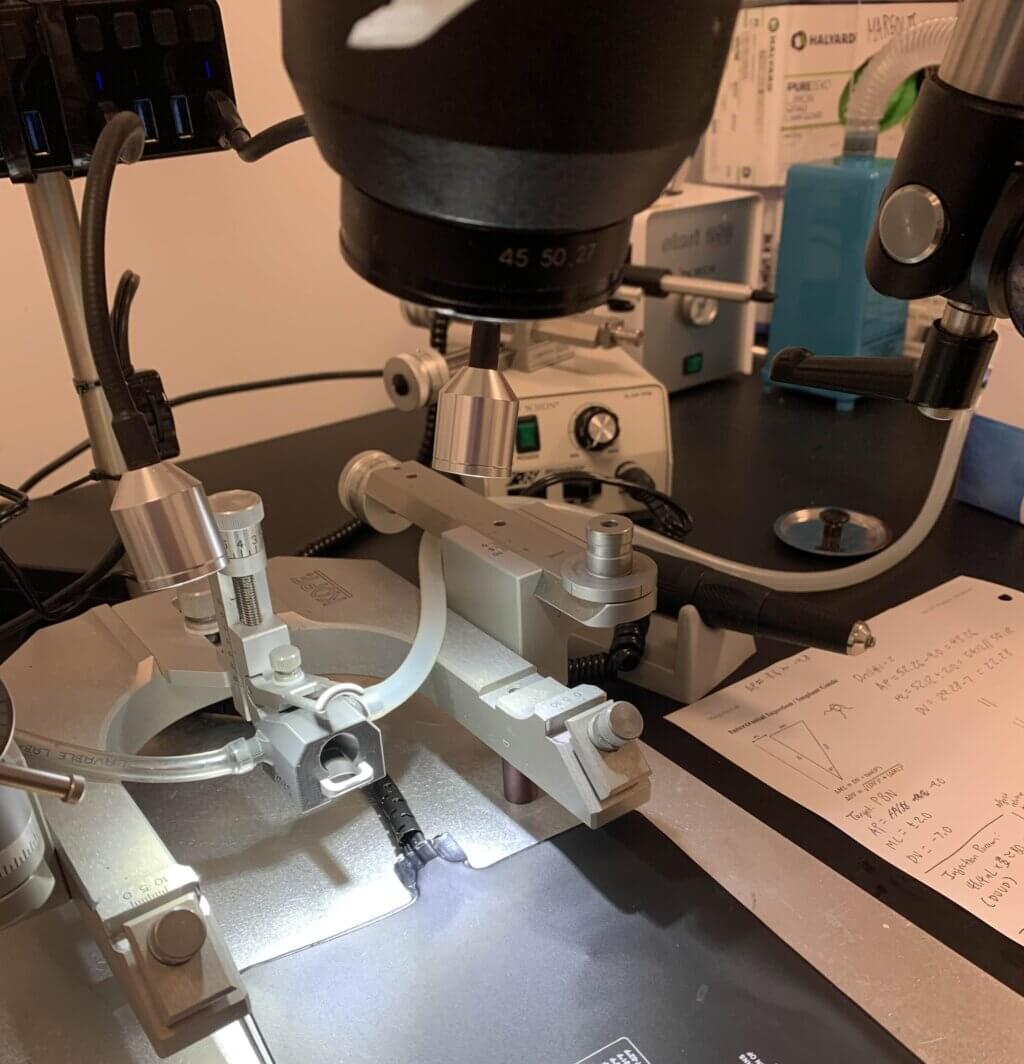

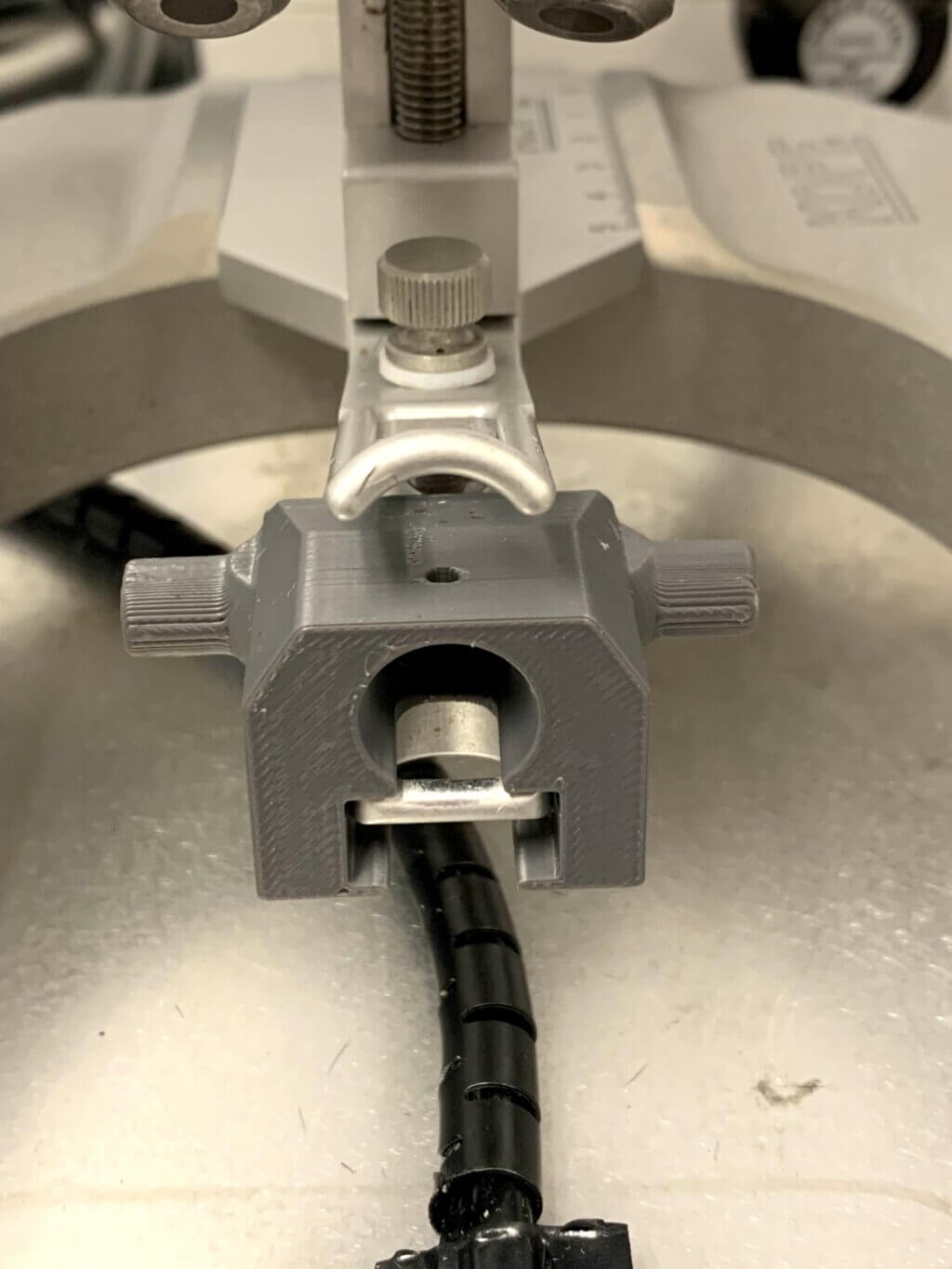

I made a nose cone for stereotaxic surgery in rodents. Stereotaxic surgery involves using coordinates from medical imaging to precisely direct a surgical instrument.

Q: Why did you want to make it?

We previously had a homemade nose cone that leaked isoflurane, an inhalable anesthetic, during surgery. 3D printing seemed like a good solution since the nose cone is small and rather parametric in shape. 3D modeling the nose cone also provides a path to change dimensions in the future (i.e. to accommodate larger or smaller rats).

Q: What was your process?

I provided measurements of the lip that the nose cone sits on when secured onto the stereotaxic frame, and Jenny Tai from the Makers Lab helped to make the computer-aided design (CAD) model from measuring the dimensions of a commercial nose cone.

Q: What was the hardest part of the process?

Making sure that the nose cone fits well on the lip, which was slightly difficult to measure since it is curved and tapered.

Q: What was your favorite part of the process?

Testing the nose cone and seeing it fit and function well during a procedure.

Q: How did this help make you a better specialist?

This experience opened my mind to the many things 3D printing can do, especially for parametric designs that can be moderately easier to draft up in CAD.

Q: What do you want to make next?

I plan on making tools to be used in stereotaxic surgery to help reduce surgery length and improve consistency between subjects. Right now, I am testing an accessory Jenny made that mounts onto the stereotaxic manipulator arm to help with accurate marking of locations on the skull for craniotomy procedures.